Needle punched non-woven fabric features and manufacturer introduction | JINHAOCHENG NONWOVEN

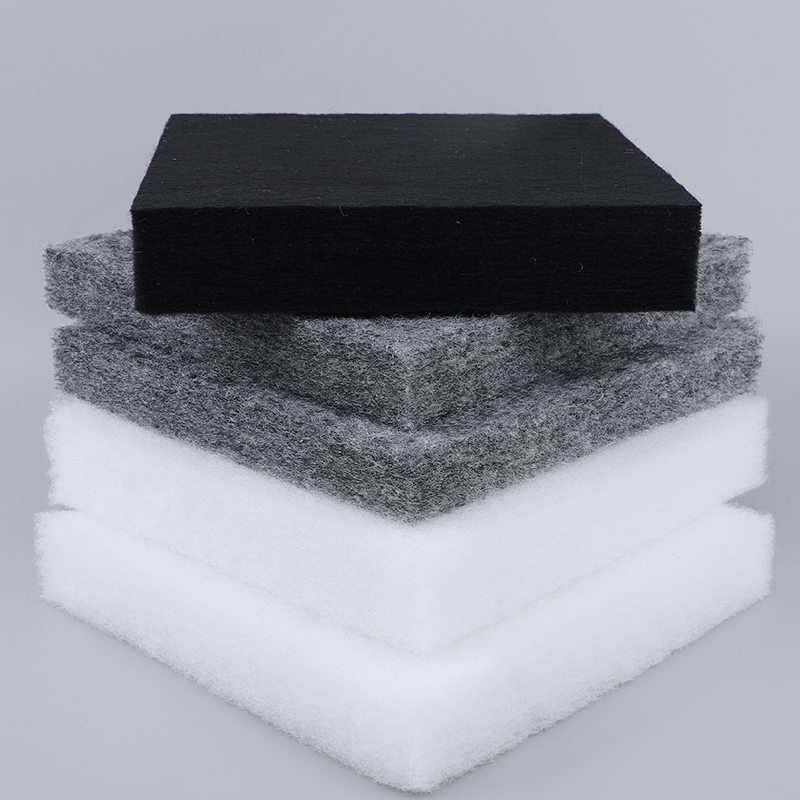

Needle punched non-woven fabric introduction:

Non-woven fabric, also known as non-woven fabric, needle-punched cotton, needle-punched non-woven fabric, etc., is produced from polyester fiber (abbreviated as PET) material and made through needle-punching process. It can be made in different thicknesses, hand feel, hardness, etc

Non-woven fabric has the characteristics of moisture-proofing, breathability, flexibility, lightness and thinness, flame retardancy, non-toxicity and odorlessness, low price and recyclability. It can be used in various industries, such as sound insulation, heat insulation, electric heating sheets, masks, clothing, medical applications, filling materials, etc

Advantages:

1. Lightweight: The main production material is polypropylene resin, with a specific gravity of only 0.9, which is only three-fifths that of cotton. It is fluffy and has a good hand feel.

2 Soft: Composed of fine fibers (2-3D), it is formed by light point hot-melt bonding. The finished product has a moderate softness and a comfortable feel.

3 Water-repellent and breathable: Polypropylene chips do not absorb water, with a moisture content of zero. The finished product has excellent water-repellent properties. Composed of 100% fibers, it is porous and has good breathability, making it easy to keep the fabric surface dry and easy to wash.

4. It can purify the air. By taking advantage of its small pores, it keeps bacteria and viruses out.

5. Non-toxic and non-irritating: The product is made from FDA food-grade raw materials and contains no other chemical components. It has stable performance, is non-toxic, odorless and does not irritate the skin.

6. Antibacterial and resistant to chemical agents: Polypropylene is a chemically inert material, resistant to insect damage, and can isolate the erosion of bacteria and insects existing in liquids. Antibacterial, alkali-resistant, and the finished product will not be affected in strength due to erosion.

7. Antibacterial property. The product is water-repellent, does not mold, and can isolate the erosion of bacteria and insects existing in the liquid, and is not prone to mold or moth damage.

8. Good physical properties. It is made by directly laying polypropylene spun filaments into a web and thermally bonding them. The strength of the product is better than that of general short-fiber products. The strength has no directionality, and the strength in the longitudinal and transverse directions is similar.

9 In terms of environmental protection, the raw material of most non-woven fabrics used is polypropylene, while that of plastic bags is polyethylene. Although the names of the two substances are similar, their chemical structures are quite different. The chemical molecular structure of polyethylene is highly stable and extremely difficult to degrade, so it takes 300 years for plastic bags to decompose completely. The chemical structure of polypropylene is not stable, and its molecular chains can easily break, thus enabling effective degradation and entering the next environmental cycle in a non-toxic form. A non-woven fabric shopping bag can be completely decomposed within 90 days. Moreover, non-woven fabric shopping bags can be reused more than 10 times, and the pollution they cause to the environment after being discarded is only 10% of that of plastic bags.

Huizhou Jinhaocheng Nonwovens Co., Ltd. is the largest needle-punched non-woven fabric factory in Guangdong Province, China, with over 20 years of research and development and production history.

Our company has a high quality team;

The product research and development center is dedicated to the development of new products and the application of new technologies;

A solid foundation for the company's long-term development;

Products have passed ISO90001: 2008 international quality management system certification.

The company currently has a number of spunlace nonwoven production lines.

Our company produces all of its products from raw materials to finished products, thus ensuring the excellent quality and diversity of the products.

The self-developed products have broken the monopoly of foreign companies on technology for many years and filled the domestic gap.

A number of products and technologies have obtained national patents.