How to Protect Tiles During Construction: The Ultimate Guide Using Premium Polyester Felt Laminated Film

Introduction

Construction and renovation projects can cause irreversible damage to your valuable tile floors, countertops, and wall surfaces. Without proper protection, tiles are vulnerable to scratches, cracks, chemical stains, and impact damage. This guide will show you how to effectively shield your surfaces using professional-grade polyester felt laminated film – the advanced non-woven floor protection material revolutionizing construction sites across Europe and America.

Why Tiles Need Special Protection During Construction

Tiles, whether ceramic, porcelain, marble, or glass, face multiple threats during renovation:

Impact Damage: Falling tools and materials can crack tiles

Scratches: Grit and debris underfoot create permanent surface damage

Chemical Stains: Paint, varnish, adhesives, and solvents can etch or discolor surfaces

Pressure Damage: Heavy equipment and concentrated weight can fracture tiles

Residue Issues: Improper protection leaves adhesive residues requiring costly cleanup

The Professional Solution: Polyester Felt Laminated Film

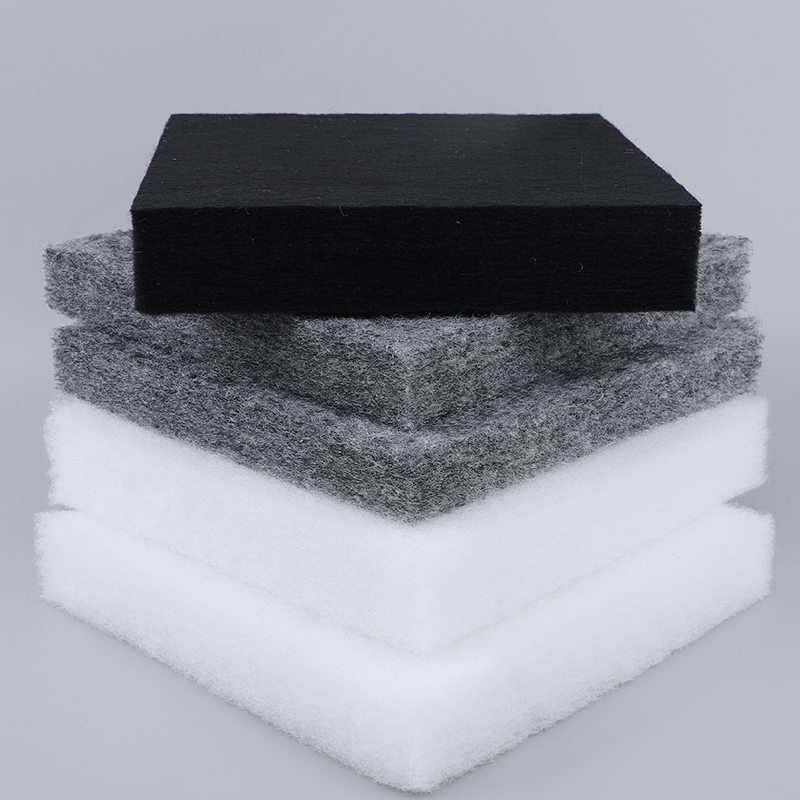

Picture 1: Waterproof self-adhesive floor protection felt fleece from Huizhou Jinhaocheng Nonwovens Co., Ltd.

What Makes This Material Exceptional?

Polyester felt laminated film represents the pinnacle of surface protection technology. This self-adhesive, multi-layered non-woven material combines the protective qualities of industrial felt with advanced polymer lamination, creating a product with unparalleled characteristics:

Key Properties and Benefits:

Self-Adhesive & No Tape Needed: Features light adhesive backing for secure placement without damaging surfaces

Multi-Surface Protection: Effective on tiles, marble, hardwood, glass walls, stainless steel, carpets, and furniture

Superior Durability: Tear-proof, heavy-duty construction withstands months of construction traffic

Complete Moisture Defense: Waterproof and water-resistant layers prevent liquid penetration

Heat & Chemical Resistance: Heat resistant and chemical-resistant against common construction materials

Safety Features: Anti-slip and non-slip surfaces prevent accidents on protected floors

Breathable Design: Prevents moisture buildup and mold formation

Residue-Free Removal: Easy removal with peel-and-stick technology leaves no adhesive marks

Easy Maintenance: Warm water cleanable surface and easy to clean spills

Installation Efficiency: Reverse wound for easy roll-out, cut-to-size customization, and easy to install interlock system

Visual Monitoring: Available in clear and blue variants for different protection needs

Environmental Consideration: Eco-friendly and temporary protection solution

Specialized Protection: Paint-resistant, varnish-proof, dust-proof, and debris-resistant

Structural Integrity: Creep-resistant, wrinkle-free surface with impact-absorbing qualities

Pressure Distribution: Pressure damage protection for heavy equipment areas

Scratch Prevention: Scratch-resistant surface preserves delicate finishes

Step-by-Step Protection Guide for Tiles

Phase 1: Preparation

Clean Thoroughly: Remove all debris, dust, and moisture from tile surfaces

Inspect for Damage: Repair any existing cracks or loose tiles before protection

Measure Areas: Calculate coverage needed for floors, walls, and countertops

Phase 2: Installation

Roll Out Material: Use the reverse wound design for easy roll-out

Cut to Size: Customize with cut-to-size flexibility for complex areas

Peel and Stick: Apply the self-adhesive backing directly to tiles

Interlock Seams: Use the easy to install interlock system for seamless coverage

Secure Edges: The light adhesive backing holds securely without additional tape

Picture 2: onstruction process for protecting the ceramic tile floor from Huizhou Jinhaocheng Nonwovens Co., Ltd.

Phase 3: During Construction

The heavy-duty material withstands continuous foot and equipment traffic

Spill Management: Waterproof layer contains liquids; simply wipe clean

Debris Control: Dust-proof surface prevents grit from reaching tiles

Phase 4: Removal and Cleanup

Peel Away: Easy removal starting from corners

Residue Check: Residue-free adhesive leaves surfaces clean

Final Clean: Any remaining marks are warm water cleanable

Dispose/R reuse: Eco-friendly material can often be reused for smaller projects

Applications Beyond Tile Protection

This versatile material provides comprehensive protection for:

Marble and Natural Stone: Chemical-resistant protection against acids and alkalis

Hardwood Floors: Breathable design prevents moisture trapping

Glass Walls and Windows: Scratch-resistant surface maintains clarity

Stainless Steel Appliances: Prevents scratches and chemical damage

Carpets and Rugs: Debris-resistant surface keeps fibers clean

Countertops and Vanities: Impact-absorbing layer against dropped tools

Why This Material Dominates European and American Markets

The popularity of polyester felt laminated film in developed markets stems from its:

Cost Efficiency: Prevents thousands in repair and replacement costs

Time Savings: Reduces cleanup time by up to 80%

Insurance Benefits: Many insurers recognize professional protection materials

Sustainability: Eco-friendly materials align with green building standards

Versatility: One solution for multiple surface types throughout the project

Manufacturing Excellence: The Chinese Advantage

When sourcing premium protection materials, provenance matters. Huizhou Jinhaocheng Nonwovens Co., Ltd., Guangdong Province's largest non-woven manufacturer, has established itself as the industry leader in advanced polyester felt laminated film production.

Why Jinhaocheng Stands Out:

Specialized Expertise: Decades of focus on high-performance non-woven technologies

R&D Investment: Continuous innovation in adhesive systems and material engineering

Quality Control: Stringent testing ensures every roll meets international standards

Export Experience: Extensive knowledge of European and American market requirements

Customization Capabilities: Cut-to-size, color variations, and specialized formulations

Scale Advantages: As Guangdong's largest facility, they offer competitive pricing without compromising quality

Environmental Commitment: Eco-friendly manufacturing processes and materials

Choosing the Right Protection Supplier

When selecting polyester felt laminated film, consider:

Material Specifications: Verify all claimed properties through samples

Manufacturer Reputation: Choose established producers like Jinhaocheng with proven export records

Customization Options: Ensure cut-to-size and color options match your project needs

Certifications: Look for international quality and environmental certifications

Sample Testing: Always test samples on your specific surfaces before bulk ordering

Picture 3: Protecting the wooden floor during construction from Huizhou Jinhaocheng Nonwovens Co., Ltd.

Conclusion

Protecting tiles during construction is not an expense but an investment in preserving your property's value. Polyester felt laminated film offers comprehensive, professional-grade protection that addresses every risk tiles face during renovation. With its self-adhesive, heavy-duty, multi-protective design, this material has become the standard for contractors and homeowners in sophisticated markets worldwide.

For businesses seeking reliable, high-quality protection materials, partnering with specialized manufacturers like Huizhou Jinhaocheng Nonwovens Co., Ltd. ensures access to cutting-edge products backed by serious manufacturing expertise. Their position as Guangdong's largest non-woven producer translates to consistent quality, competitive pricing, and the technical knowledge needed for complex projects.

Remember: Proper protection today prevents costly repairs tomorrow. Choose professional solutions, protect comprehensively, and renovate with confidence.