How to Protect Hardwood Floors During Remodeling: A Guide with OEM Insights

Hardwood floors are a valuable and elegant feature in any home, but they are highly vulnerable during remodeling projects. Dust, debris, heavy tools, and foot traffic can cause scratches, stains, and permanent damage. Fortunately, with proper protection, you can keep your floors pristine. In this guide, we’ll explore effective strategies and highlight why choosing the right protective materials—such as non-woven floor protection films and rolls—matters. As a factory with over 20 years of expertise in non-woven research, production, and customization, we specialize in OEM/ODM manufacturing of high-quality floor protection solutions for markets in Europe, the USA, Australia, the Middle East, and beyond.

Picture 1: Blue floor protection roll from Huizhou Jinhaocheng Nonwovens Co., Ltd.

Why Protecting Hardwood Floors is Crucial

Remodeling generates significant amounts of dust, sharp objects, and heavy equipment. Even minor abrasions or moisture exposure can compromise the finish and integrity of hardwood floors. Proper protection:

Prevents costly refinishing or replacement

Reduces cleanup time

Maintains the aesthetic and value of your home

Step-by-Step Guide to Protecting Hardwood Floors

1. Clear and Clean the Area

Begin by removing all furniture and fixtures. Thoroughly clean the floor to eliminate any grit or dust that could scratch the surface once covered.

2. Choose the Right Protective Materials

Not all floor protection is created equal. For optimal results, use professional-grade materials:

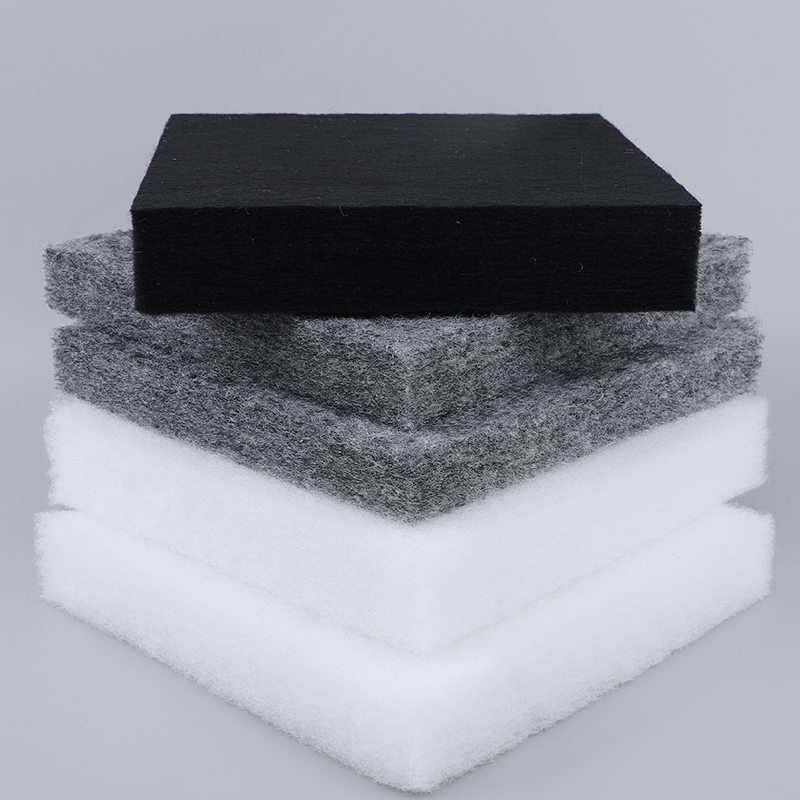

Non-woven Floor Protection Film: Ideal for short to mid-term projects. It’s lightweight, dust-proof, and offers a non-slip surface. Unlike plastic, non-woven materials are breathable, reducing condensation risks.

Non-woven Floor Protection Rolls: Better suited for larger areas or longer durations. These rolls are durable, resistant to tears, and provide a cushioned layer against impacts.

Tip from the factory: As a specialized manufacturer with two decades of R&D in non-woven textiles, we produce customized protection films and rolls that balance durability, flexibility, and protection. Our OEM/ODM services ensure products meet specific project requirements, from thickness to adhesive properties.

3. Install Underlayment for Added Cushioning

For heavy remodeling work (e.g., kitchen renovations), consider adding an underlayment beneath the non-woven layer. Felt or foam underlayment can absorb shocks from falling tools or materials.

4. Secure the Coverage

Lay the non-woven film or rolls smoothly, ensuring seams overlap by at least 2 inches. Use painter’s tape (low-adhesive) to secure edges to baseboards—never use duct tape, which can leave residues.

5. Maintain Protection During the Project

Regularly inspect the protective layer for tears or displacement. Replace damaged sections promptly to avoid exposed areas.

Picture 2: Gray floor protection cover fleece from Huizhou Jinhaocheng Nonwovens Co., Ltd.

6. Post-Remodeling Cleanup

Carefully remove the protection materials. The non-woven fabric should lift cleanly without leaving debris. A final sweep and damp mop will restore your floors.

Why Choose Non-Woven Protection Over Alternatives?

Plastic Sheeting: Slippery, traps moisture, and tears easily.

Cardboard: Absorbs moisture, decomposes, and offers limited cushioning.

Non-woven Materials: Breathable, tear-resistant, non-slip, and eco-friendly. They provide superior protection against scratches, spills, and heavy traffic.

Selecting the Right Chinese Factory for OEM Non-Woven Floor Protection

When sourcing non-woven floor protection products, partnering with an experienced factory is key. Here’s what to look for:

Expertise in Non-Woven R&D: Choose a manufacturer with a proven track record in non-woven technology. Our factory has invested 20+ years in developing advanced, customizable non-woven fabrics for floor protection.

OEM/ODM Capabilities: Ensure the factory can tailor products to your specifications—size, thickness, color, branding, and packaging. We offer comprehensive OEM/ODM services, catering to clients across Europe, the USA, Australia, and the Middle East.

Quality and Compliance: Verify international quality standards (e.g., ISO, CE) and eco-friendly practices. Our products are designed to meet stringent global requirements.

Supply Chain Reliability: A factory with robust export experience ensures timely delivery and consistent quality. We have extensive experience supplying to developed regions worldwide.

Competitive Pricing: Leverage direct factory pricing without sacrificing quality. As a manufacturer, we provide cost-effective solutions for bulk orders.

Conclusion

Protecting hardwood floors during remodeling is an investment in your home’s longevity. By selecting professional-grade non-woven protection films or rolls, you can prevent damage and simplify cleanup. For businesses and contractors, partnering with a reliable Chinese factory for OEM non-woven floor protection products ensures high-quality, customizable solutions. With over 20 years in non-woven production and OEM/ODM services, we are committed to delivering superior floor protection products for global markets. Protect wisely, remodel confidently.

Picture 3: White floor protection cover felt roll Loading and shipping in containers from Huizhou Jinhaocheng Nonwovens Co., Ltd.